Where precision meets artistry. Our cutting-edge facility houses the most advanced equipment and master craftsmen dedicated to creating automotive luxury.

Years Experience

Sq Ft Facility

Projects Completed

Production Capability

Take a tour through our specialized work areas, each designed for precision and excellence

Our fabrication area houses precision CNC machines, cutting-edge tools, and expert craftsmen who transform raw materials into custom automotive components with unmatched accuracy.

Master craftsmen work with premium leathers and exotic materials to create stunning interior pieces that combine luxury aesthetics with exceptional durability and comfort.

Our main production floor brings together all elements of the build process, where skilled technicians assemble, test, and perfect every custom interior component.

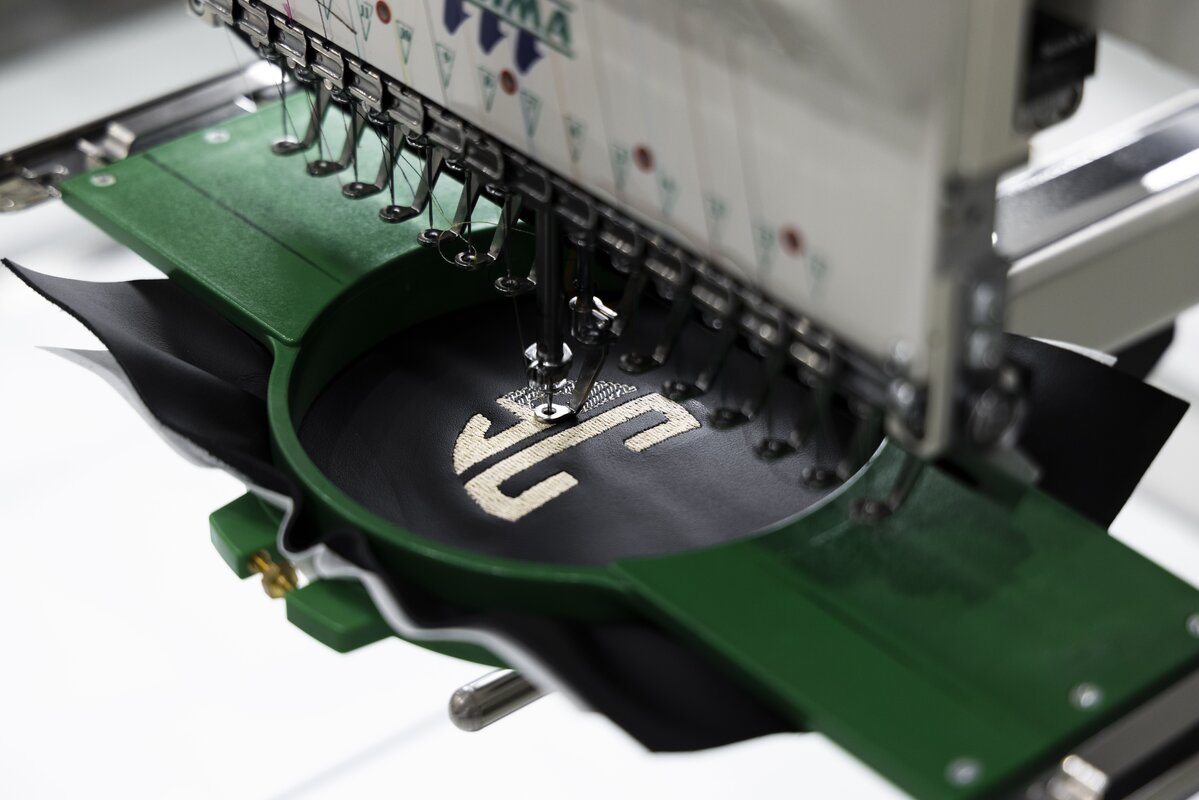

Precision embroidery and quilting machines create intricate patterns and custom designs, adding personalized touches that make each interior truly unique and distinctive.

Our facility features the latest in precision manufacturing and craftsmanship technology

State-of-the-art embroidery machines engineered for custom automotive interiors, delivering intricate designs and logos with unmatched accuracy.

High-precision laser systems for detailed engraving and cutting with exceptional accuracy.

Advanced machining dedicated to the automotive industry — building precision metal parts that ensure perfect fit, strength, and reliability.

Traditional craftsmanship meets modern precision for custom wood trim and accents.

Optimal conditions for material storage and precision work with temperature and humidity control.

Rigorous inspection processes ensure every component meets our exacting standards.